|

|

|

![]()

![]()

Shu kae industrial Co. Ltd. has been established since 1977. The company originally set out making high quality Dust Caps. However, as the company grew it started to manufacture other components associated with the Loudspeaker. Our production process utilizes a S.P.C. ( Statistics Process Control ) management system. It means we are monitoring every single process to produce the best possible product and constantly develop new products to match customers' needs. SHU KAE INDUSTRIAL GROUP LIMITED is one of Asia's leading Loudspeaker components manufactures, the company has expanded to 6 factories and has customers around the world.

A Milestone In Stereo Technology

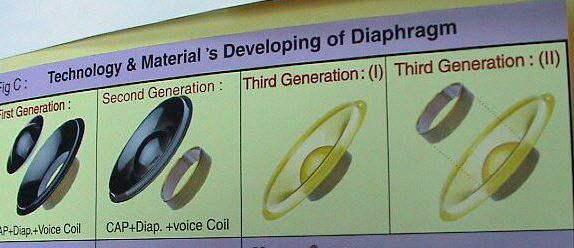

The materials used for diaphragms have changed from paper to resin, to metal, and now to Kapton. In addition, the design of diaphragm has changed according to the type of material used, from the first generation to the current third generation. This diaphragm illustrating that the greatest breakthrough in the move from the second to the third generation was the use of Kapton JP/JPB. The first significant characteristic of Kapton is its resistance to heat, making it suitable for use in car stereos. It can be formed in a single mold, significantly reducing production time and waste, enabling economy labor and material. However, the most important thing is that, because of the lower diaphragm forming temperature and breakthroughs in the molds and materials used during the production process, it has been possible to lengthen and deepen the tail of the dustcover. In addition, after molding, the dustcover will retain its original size and not shrink due to cooling. This superior production efficiency is the secret behind the success of the third generation diaphragm.

SHU KAE INDUSTRIAL GROUP HEAD OFFICE & FACTORIES DETAILS